Marble is one of the most admired materials for art and architecture. Formed from calcite or dolomite crystals that are subjected to extreme heat and pressure in the interior of the Earth, this brilliant white stone is used in some of the world's most beautiful sculptures, buildings and furniture. Marble was historically mined by the ancient Greeks and continues to be mined from quarries today, all over the world. Most of the natural stones are extracted from the quarries steps nearby by the following. Locating a potential quarrying site is the first step in the mining process. Next, a mining company needs to apply for all of the required licenses from the local, state, and federal government, a process that can take months to years. Once mining has begun, there may be several months of digging before any marble is extracted from the quarry. Overburden, or dirt on top of the desirable ore, needs to be extracted before blocks of marble can be removed. Mining marble blocks from the wall of the quarry starts with a "bench wall." The bench wall is a large section of marble along a vertical wall that is cut with diamond cables, drills, and torches. After the blocks are extracted from the quarry, they'll go through further processing to match their intended purpose. For tiles, the marble is cut into stone billets and polished to a smooth sheen. Process 1 Process 2 Process 3 Process 4 Process 5 Process 6 Not even the lack of one of them is acceptable!What we do?

How Does Marble Get Mined From a Quarry?

Production of Slabs

Block Strengthening

Cutting

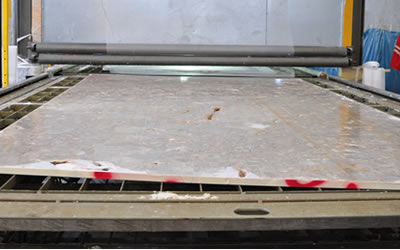

Epoxy Line

Polishing Line

Stocking

Loading