What are Natural Stone CNC Works?

Natural stone CNC (Computer Numerical Control) works involve the use of computer-controlled machines in the processing and shaping of natural stones. This technology allows for the precise cutting, carving, and shaping of stones, resulting in high-quality aesthetic and functional outcomes. CNC machines are used in the processing of various natural stones such as marble, granite, and travertine.

Advantages of Natural Stone CNC Works

-

High Precision: CNC machines allow for designs to be created in a computer environment and applied to the stone with high precision. This enables the creation of complex patterns and detailed motifs.

-

Repeatability: CNC technology allows for the same design to be produced multiple times in exactly the same way. This ensures consistency, especially in large-scale projects.

-

Time Savings: Compared to traditional methods, CNC machines significantly accelerate the processing of natural stones. This allows projects to be completed in a shorter time frame.

-

Advanced Design Possibilities: When combined with computer-aided design (CAD) software, CNC machines enable the easy creation of complex and innovative designs. This fosters greater creativity in architectural projects and artistic works.

-

Reduced Waste: CNC technology allows for more efficient use of natural stone. The precision in cutting and shaping minimizes material waste.

Applications of Natural Stone CNC Works

-

Architectural Applications: Natural stone CNC works are frequently used to create aesthetic details in the interiors and exteriors of buildings. Marble cladding, columns, cornices, and other architectural elements can be processed with high precision using CNC machines.

-

Artworks: Artists can use CNC technology to create sculptures, panels, and other artistic works from natural stones. This allows for unrestricted expression of the artist's creativity.

-

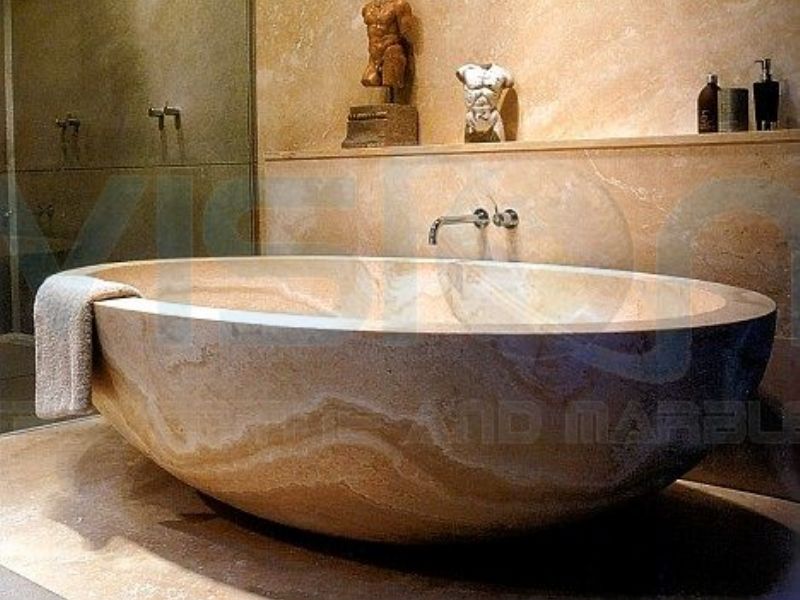

Interior Design: Interior elements such as kitchen countertops, bathroom sinks, and fireplace cladding gain high-quality and aesthetic appeal through CNC processing of natural stones.

-

Exterior Design: Natural stone CNC works are also utilized in areas such as garden paths, terraces, and exterior cladding. This enhances the style and functionality of outdoor spaces.

-

Design Objects: Designs for tables, chairs, and decorative objects made from natural stones can be more refined and detailed through CNC machining.

Conclusion

Natural stone CNC works represent a revolutionary development in the stone processing industry. This technology offers high precision, time savings, and improved design possibilities, encompassing a wide range of applications from architectural projects to artistic works. The processing of natural stones with computer-controlled machines helps achieve high-quality results both aesthetically and functionally, while also highlighting the natural beauty of the stone. In this context, natural stone CNC works have become an integral part of modern architecture and art.